Metal Skills Lab

Metal Cube

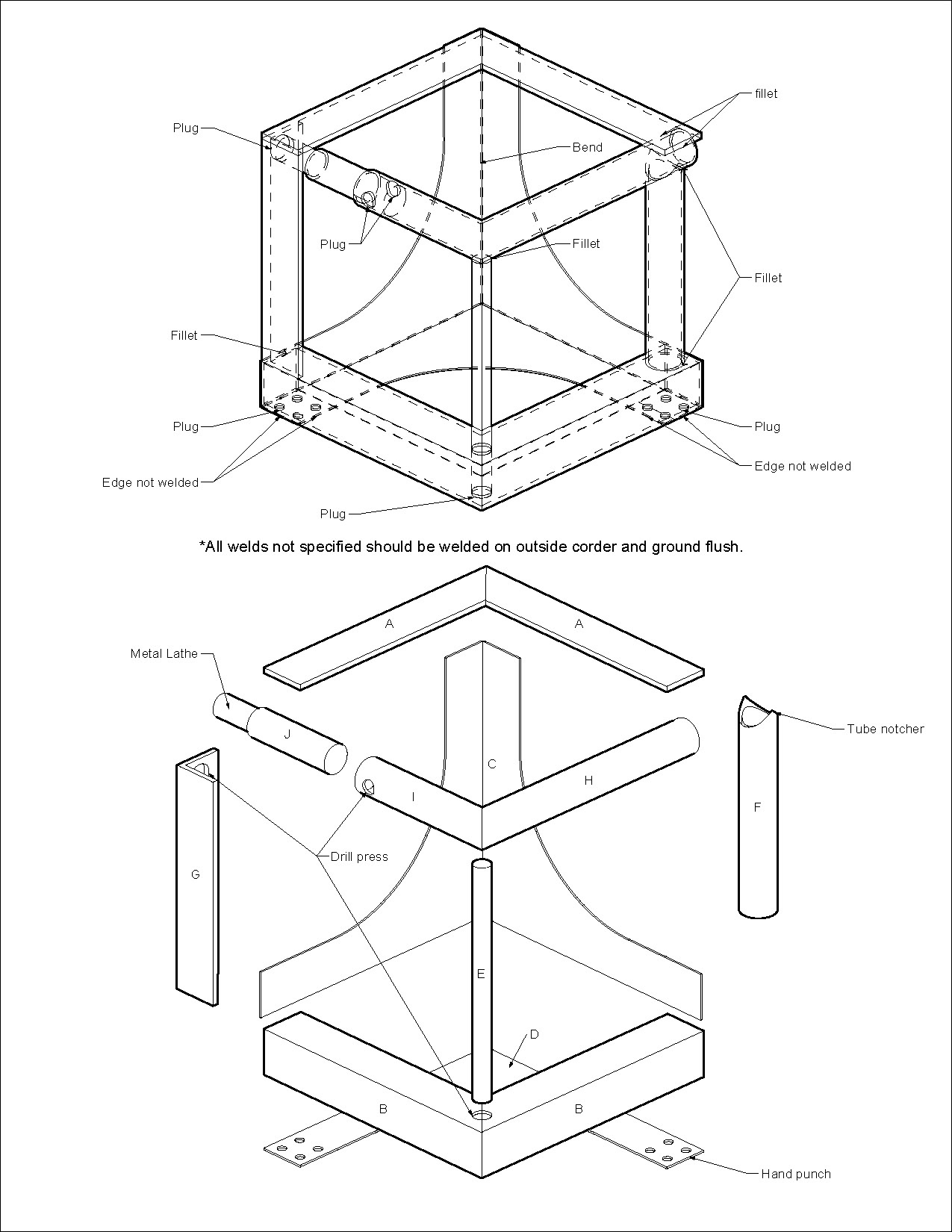

Through the process of fabricating the metal cube, you will be introduced to many of the tools and techniques used in metalworking. Working as a team, you will see the challenge through different views and learn from each other’s experiences.

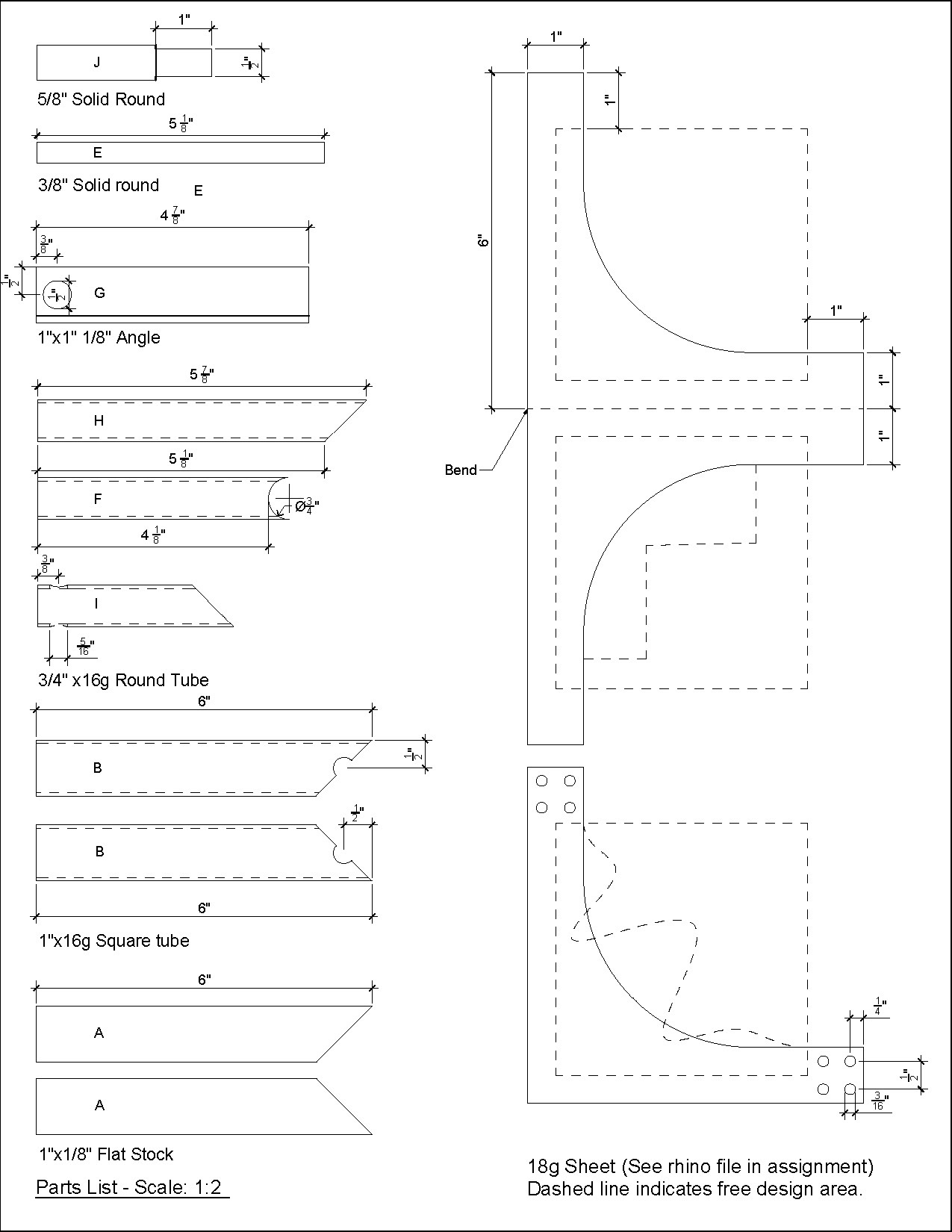

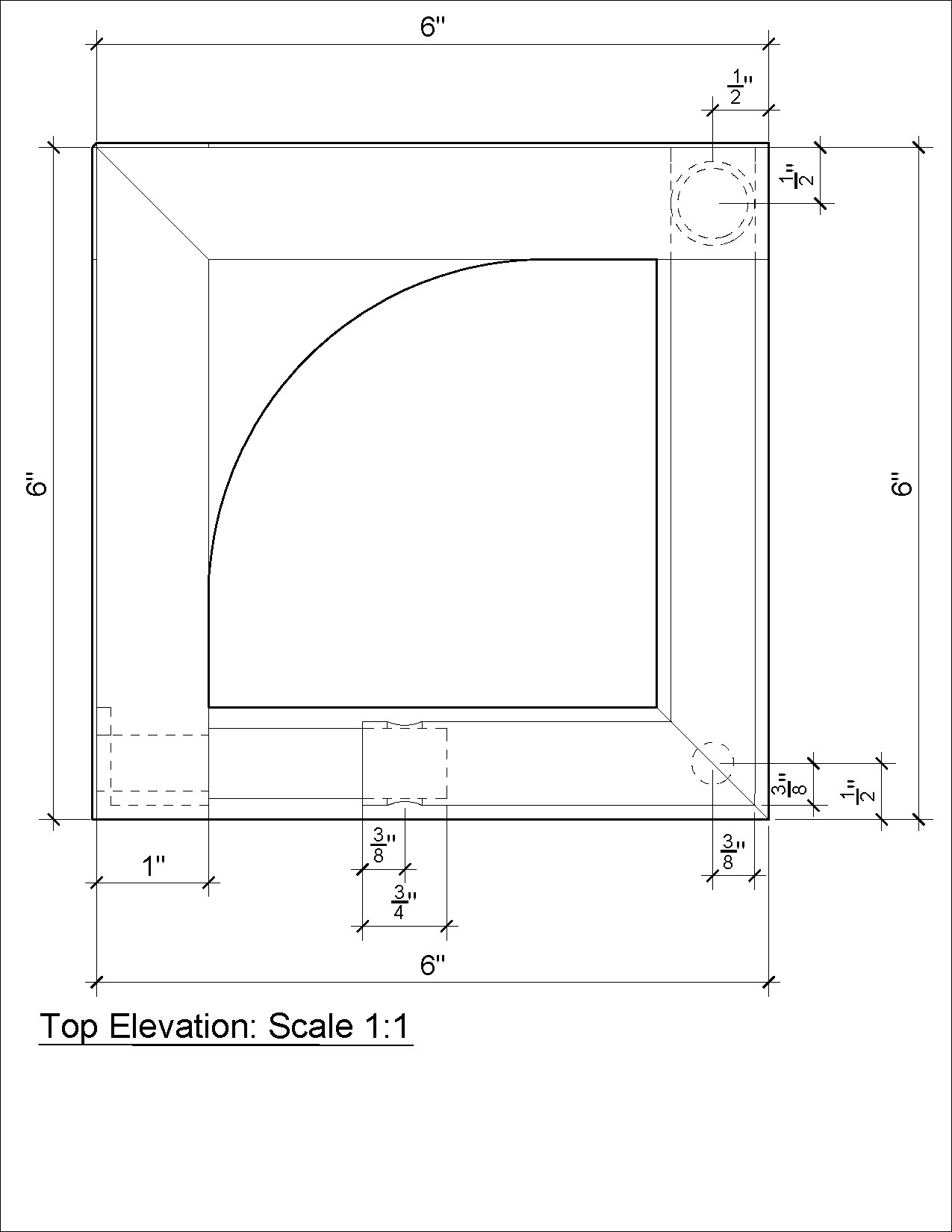

As a team, you will fabricate the cube detailed below.

- Each connection (cube corner) should be practiced before attempting the cube, these practice connections should be documented and turned in with the cube

- All edges should be ground or filed. Cutting, drilling, and shearing all create sharp edges that are dangerous to handle.

- Remove welding berries and other fabrication imperfections.

- Link to a RHINO 3D file of the cube for reference

- All edges should be ground or filed. Cutting, drilling, and shearing all create sharp edges that are dangerous to handle.

- Remove welding berries and other fabrication imperfections.

- Link to a RHINO 3D file of the cube for reference

Documentation:

- Take notes throughout the fabrication process. It helps transform your experience into knowledge.

- Photograph each stage of fabrication to document your progress. Photograph parts before and after you cut or drill them. Photograph welds before you grind them.

- Take photos of each team member working. Participation is part of the assessment. Each member of the team must have the opportunity to learn these techniques.

Process:

- Start by cutting the pieces for your cube. Remember, your cuts can only be as accurate as your marks. When doing this, cut extra pieces to practice each corner before you attempt the cube. Extras do not need to be full length but should be big enough to clamp down and handle (~3”). This may take multiple attempts.

- Each team member should take a turn with each process to get a feel for the machines. You are building your skills together, don’t just have your best welder complete the cube.

- Think through the order of operations. Some processes might need to happen before the others.

- Seek guidance from your welding consultant, Eli.

Equipment Used

Horizontal Bandsaw, MIG welder, highspeed sanders, 90 degree die grinder, drill press, metal lathe, CNC plasma cutter, Baileigh sheer, sheet metal brake, tubing notcher

Finish

Clean and finish the cube with primer and spray paint.